Hybond Machine Systems

Hybond Machine Systems; providing Comprehensive Industrial Bonding Equipment & Solutions

Born from the vision of providing a single source which offers both adhesives and application equipment; Hybond Machine Systems Division has experience in everything from large complex robot gluing & packing lines, large scale, high-volume roll coating and pressing equipment, through to medium sized coating, spraying and cutting applications, 2, 3 and 5 axis robots, right down to small, very precise Cartesian desktop robots.

With a focus on the latest in high speed processing technology, designed to give the highest levels of guaranteed repeatability and return on investment, our machine solutions are robust; designed and built for the long road ahead.

Imagine an adhesive supplier who really understands application equipment and has the knowledge and experience to make the two work in harmony. Now imagine having an equipment supplier whose team hold decades of experience with adhesives, and know how to achieve optimum performance and efficiency; with Hybond, you truly have both.

WHATEVER YOUR INDUSTRY

- WOODWORKING & FURNITURE

- AUTOMOTIVE

- PACKAGING

- MARINE & INFLATABLE STRUCTURES

- AEROSPACE

- RAIL

WHATEVER YOU’RE BONDING

- AUTOMATE

- SPEED UP

- REDUCE WASTE

- IMPROVE QUALITY

- ELIMINATE HAZARDS

- INCREASE OUTPUT

Your Machine Systems Project

The Process

We work with customers from start to finish. At an initial meeting we will fully scope your project and collect data on the bonding task in hand. We will ask detailed questions to gain an overview of what the completed project has to be capable of achieving, and will give initial guidance as to what technology would be most relevant.

The next stage will typically be to carry out initial trials, and possibly run lab tests to confirm the suitability of the chosen technology to achieve the needed results, be that accelerated aging, stress testing, climatic testing etc.

A further step is to produce outline drawings and costs, together with details of expected throughput, future possible requirements, floor layouts, in-feed / out-feed processes, return on investment, etc. This process continues right through to site surveys, advice on power requirements, installation, operator training and then on to maintenance and monitoring / auditing of results to ensure ongoing compliance.

PRODUCTION LINES

As a manufacturer, no matter what you’re making, chances are your production process will include at least one, or perhaps multiple, bonding stages. Hybond Machine Systems can help you to achieve faster, stronger, more cost-efficient bonds with our bespoke machine solutions. We’ll take you from your initial brief, to comprehensive consultation, installation and beyond.

MACHINERY SUPPLY

Need something a little more off the peg? Let Hybond source for you the best in Industrial Bonding Machinery. We will provide you with the right equipment for your needs, and can provide aftercare and servicing too. Visit the news section of our website for regular machinery promotions and deals.

ON SITE SUPPORT

When Hybond Machine Systems install your bespoke bonding line solution, rest assured we’re always on hand to provide comprehensive on-site support and after care. We offer multiple support services including routine machinery audits, production trials and system fine tuning.

LABORATORY FACILITY

Working hand in hand with Hybond Machine Systems are Hybond’s fully equipped Technical Backup & Lab Facilities . Based at our Shropshire head offices, the Hybond laboratory carries out comprehensive product testing to ensure customers achieve the very best in bond quality.

A Hybond Machine Systems installation in action. Here we see automated adhesive application & box closing function applied to a customer’s packaging process.

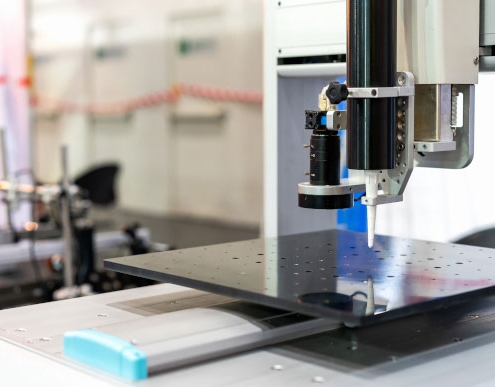

A desk top robot quickly, accurately and fully automatically applies Cyanoacrylate to a customer’s component. These amazing machines can be programmed using the part designers CAD files, using standard CNC programming language or even by simple input on the built in control panel.