Technical Backup & Lab Facilities

At Hybond, we understand that the quality and integrity of your final product is what’s important in your selection of an adhesive partner.

We know how important it is to keep your production going and to eliminate downtime, rejects or reworks.

Our focus is always to provide repeatability in the bonding process, appropriate to your requirements. We have a particular wealth of experience in the automotive and BTR sector, and specialist knowledge of surface energy measurement of difficult surfaces together with our own plasma treatment facility.

During more than 2 decades working with adhesives, additives, coatings and their application technologies, Hybond have accumulated a wealth of knowledge and intellectual property.

We have also developed a comprehensively equipped materials laboratory run by our full time PhD Chemist.

We have our own in-house bonding workshop with many types of application equipment and a fully equipped laboratory including adhesion testing and climate chamber test facilities.

In addition to working with our own customers, we offer consultancy and testing services to the whole of the adhesives manufacturing industry.

We will continue to develop new and exciting solutions to bonding and processing problems, even by means of formulating and testing a completely new material if required.

How does this benefit you, the customer?

In a word; CONFIDENCE.

Confidence to answer questions like these;

- Will the parts I am producing pass my OEM customers climate testing? We will do the test for you so that you already have the answer.

- Will my new design of kitchen door will be likely to pass the relevant FIRA test? We will put it through the test and give you the results.

- I need to know if a Hybond adhesive is as good as, or better than another one? We can do comparative stress tests on your behalf and report on the results.

- Is my bonded product suitable for export to a country with extreme cold conditions? We can test your bonded product down to -40°C for you.

- What about high temperature resistance, UV resistance, resistance to peel, shear, creep, is my bond-line consistent, what if I could examine it under a microscope, etc?

The list is endless. No problem to us, we have the tools, the knowledge and experience and we are here to help!

Our capabilities include: everything from basic viscosity and solids analysis, to peel, shear, and joint-break testing and includes microscope analysis of bond line integrity, accelerated aging testing, surface energy analysis, right up to full climate chamber testing for automotive applications.

In addition, many customers want to establish a benchmark for adhesive performance and so we carry out regular quality audits on site with repeat testing of bonded materials to ensure to ensure performance standards are being met.

Standard Packages

- Consultation of customers individual testing routines. Production of full documented procedures and protocols for testing adhesive bonds.

- Full day including consultancy and/or use of all equipment and Technical Service Report, POA.

- Individual climate chamber or tensometer test.

- Consultancy or testing not including climate chamber or tensometer but including other capabilities as required POA.

- Other types of work available, such as 90-day heat ageing, cyclical climate testing, by individual quotation.

- Consultation on joint design or material selection.

Example of Services Offered

Data Collection

Example 1

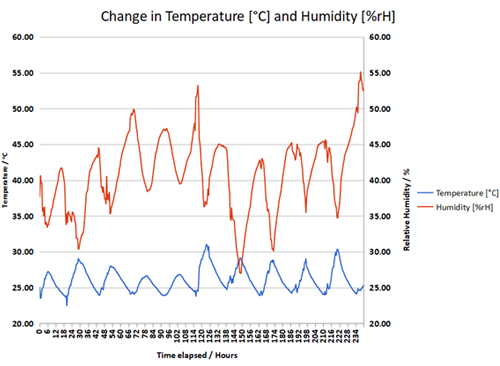

Figure above shows data collected by placing a data logging device on a customer’s premises to determine exact environmental conditions being experienced over a set period of time.

Figure 1 – Graph showing temperature change during the ten days the data logger was active

Data Collection

Example 2

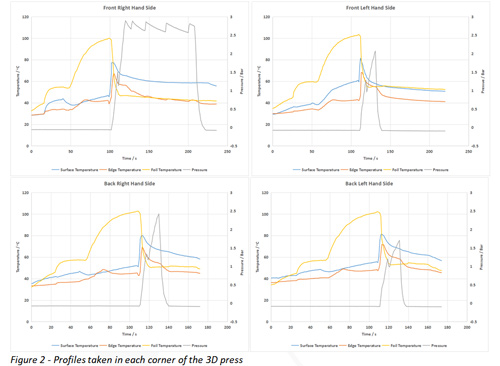

Example above shows 4 runs of data collected from a customer’s process, it can be seen that in 3 of them, there is an issue with pressure dropping off prematurely. The customer had been unaware of this and was having difficulty solving some bonding issues. Hybond Technical Service were called to site and were able to expose the problem using data logging equipment.

*Figure 2 – Profiles taken in each corner of the 3D press

Data Analysis

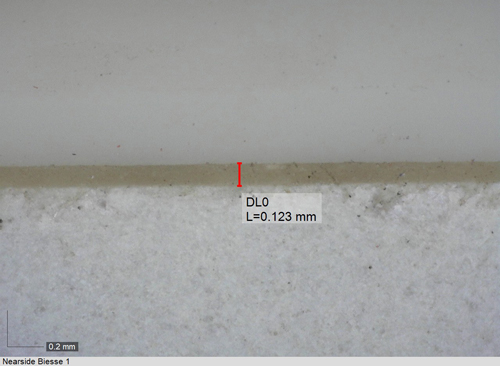

Example above shows analysis of an edge band panel following a request to Hybond Technical Service to ascertain the quality of a bond being achieved by examining it under a digital microscope and scoring the bond line, which was not possible to do with the naked eye.