https://www.hybond.org.uk/wp-content/uploads/2025/10/Hybond-Tensometer-Testing.jpg

325

400

admin@hybond

https://www.hybond.org.uk/wp-content/uploads/2020/11/technology-logo.png

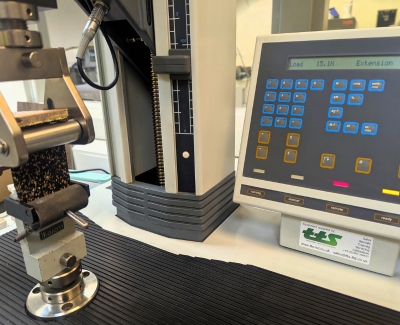

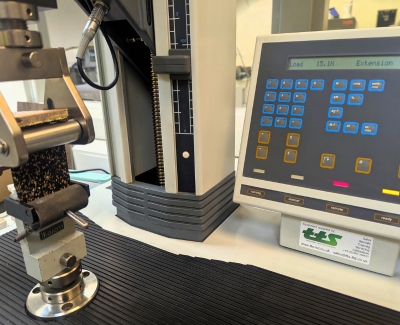

admin@hybond2025-10-20 15:17:582025-10-20 16:00:04Testing the Limits: A Look at Hybond’s Advanced Tensile Testing

https://www.hybond.org.uk/wp-content/uploads/2025/10/Hybond-Tensometer-Testing.jpg

325

400

admin@hybond

https://www.hybond.org.uk/wp-content/uploads/2020/11/technology-logo.png

admin@hybond2025-10-20 15:17:582025-10-20 16:00:04Testing the Limits: A Look at Hybond’s Advanced Tensile Testing

Aerospace & Rail Interiors.

marine, inflatable structures, lighter-than-air vehicles.

3D pressing, laminating, edgebanding, postforming, joinery.

Hybond Innovation:

Adhesives, Additives, Coatings

& Application Solutions

Welcome to Hybond

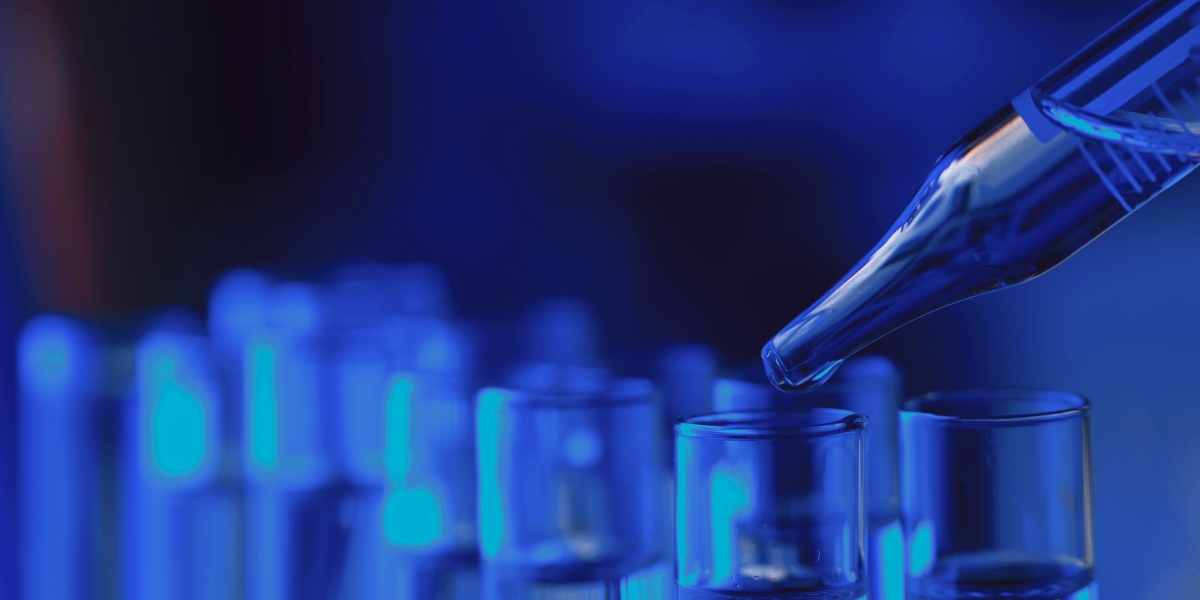

Based centrally in Shropshire, we are proud to be recognised as leading adhesive specialists in the UK, supplying high-quality industrial adhesives and solutions to customers nationwide. Our office, warehouse, laboratory and demo area are in one convenient location, making it easy to visit and discover how we can support you.

As trusted adhesive suppliers, we focus on providing complete solutions for your bonding requirements. Whether you need consultation, application trials, adhesive application equipment, product testing, or the development of a bespoke adhesive solution to solve a complex bonding challenge, we are here to help.

Our portfolio includes a comprehensive selection of adhesives and sealants, all tailored to meet the demands of your specific applications. Our aim is to help you bond materials to the highest standard, within your cost and time parameters.

Markets

Markets

Automotive

With an in-depth knowledge and collectively, decades of experience in supplying to the second-tier automotive component manufacturing sector, Hybond are ideally placed to offer the kind of service, products and competitive pricing that is critical to this market.

Aerospace & Rail

We are delighted to be continually expanding our offering within this sector, and bring with us a wealth of knowledge and expertise garnered from decades of work within neighbouring automotive industries.

Marine & Inflatable Structures

Our team hold a wealth of knowledge regarding the best adhesive products and proven bonding methods for those producing goods within the Marine and Inflatables market place.

Packaging

High-speed, automated end of line packing and case-closing operations are where our adhesives and application equipment are commonly to be found.

Woodworking & Furniture Adhesives

In the furniture industry is where it all began for Hybond. 20 years supplying to major manufacturers, including some of the largest operations in the UK.

Hybond Brands

Hybond Brands

XtraBOND

PU & Liquid Adhesives

XtraMELT

Hot Melt Adhesives

XtraLOK

Water Based Adhesives

PyroBOND

Fire Retardant Adhesives

XtraTHERM

Auto Application Systems

Hybond Services

Hybond Services

Services Overview

Technical Backup & Lab

Process Review Service

Machine Systems

3D Pressing Expertise

Latest News

https://www.hybond.org.uk/wp-content/uploads/2025/10/Hybond-Tensometer-Testing.jpg

325

400

admin@hybond

https://www.hybond.org.uk/wp-content/uploads/2020/11/technology-logo.png

admin@hybond2025-10-20 15:17:582025-10-20 16:00:04Testing the Limits: A Look at Hybond’s Advanced Tensile Testing

https://www.hybond.org.uk/wp-content/uploads/2025/10/Hybond-Tensometer-Testing.jpg

325

400

admin@hybond

https://www.hybond.org.uk/wp-content/uploads/2020/11/technology-logo.png

admin@hybond2025-10-20 15:17:582025-10-20 16:00:04Testing the Limits: A Look at Hybond’s Advanced Tensile Testing

Hybond Insight: A behind-the-scenes look inside our adhesives testing lab

Hybond Insight: Navigating bonding challenges within PIR production

Interested in what we have to offer and want to get in touch?

Hybond

Grange Business Park, Lancaster Road

Shrewsbury, Shropshire, SY1 3LG

Tel: 0800 542 3491

Sales: 0800 316 1250

Fax: 0800 316 1244

Email: sales@hybond.org.uk

Copyright Hybond 2025